Checklist For Fitting PML Small Block Valve Covers

This document is intended for PML perimeter mount Chevy small block valve covers for 1959 to 1986 heads. The process generally applies for checking if valve covers will work in any engine build.

PML provides this checklist to make sure you get valve covers that you love looking at and will work on your engine. With that in mind we have put together this checklist.

Disclaimer - Read This:

- PML does not recommend any of the modifications below. We are sharing suggestions from other customers. What works for one configuration may not work for yours. If these topics are not something you are comfortable with, talk with an engine builder.

- When building an engine, it's common for pieces not to fit together perfectly. Thicker gaskets, some grinding, modification, tweaking and finagling may be needed.

- We have heard of engine builders who grind off part of our valve covers to make additional clearance. We cannot warranty our products once modified or accept returns in any condition except new.

Before You Buy Checklist

1. Review PML Return Policy and Warranty

2. Understand How PML Checks Each Cover

At PML, we fit each valve cover we make on a GM cylinder head with standard stamped steel rocker arms.

We verify the flatness of the gasket flange surface is within tolerance (+/- 0.020 inch) and visually check for any defects.

3. Select the Finish for the PML Valve Covers

All PML parts are sand cast aluminum. Sand cast aluminum parts have the texture of sand. Because of the sand casting process, no two parts are identical. We hand pick each set to give the customer a matched pair.

PML valve covers do not feel or look the same as chrome, stamped steel or die cast aluminum parts. Original 1960s Corvette valve covers are die castings, not sand castings, have a different look and feel.

PML valve covers come in four different finishes:

as cast, orange powder coated, black powder coated, and polished

The as-cast finish is the natural aluminum sand cast part. It will be a dull silver-grey and the texture will be rough like sand.

Powder coating is very durable and is baked on to the cover. On a powder coated part, you will see and feel some sand-like texture. It is similar to an orange peel. For a custom color or to match a color, purchase the as-cast finish part and work with a powder coater near you.

Our polish finish parts are not polished between the fins and the script. Polished sand cast aluminum parts show the normal characteristics of a casting. Polished sand cast aluminum valve covers will have some imperfections.

Read more about PML Construction and Finishes.

4. Breather, PCV, and Oil Fill Holes

PML small block Chevy engine valve covers can be machined for PCV, oil fill, and breather holes without messing up the script and fins!

About half of our customers require PCV, breather and oil fill holes on the valve covers. Machining holes is an option and an additional cost.

See the pictures and read about the PML design for in this PDF about Oil Fill, Breather, and PCV with PML Valve Covers.

5. Verify Clearance in the Engine Compartment for Larger Valve Covers

PML valve covers are about 3.3 inches tall from the flange surface to the top of the script or fins. See complete dimensions.

6. Check Roller Rocker Height

Does the engine have roller rockers? If so, are PML valve covers tall enough on the inside? From the gasket surface to the inside top, PML valve covers have about 2.75 inches. See dimensions.

There is no correlation betwen roller rocker ratio and fitment of our valve covers. You will need to check the actual physical size of the parts.

PML valve covers will not work with shaft mounted roller rockers.

Engine configurations vary greatly. PML does not recommend or endorse the use of any particular roller rocker system or engine configuration.

7. If There Are Roller Rockers, Measure Space Available Between Rocker Arms

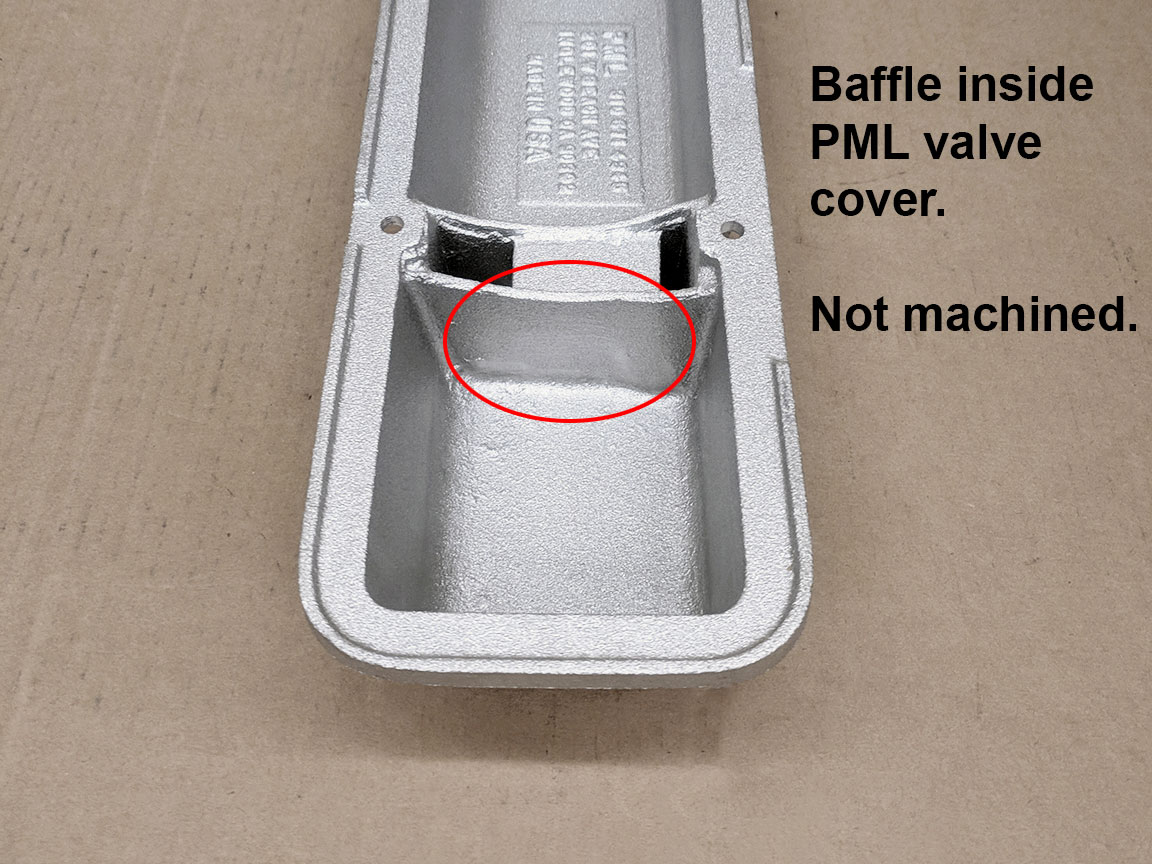

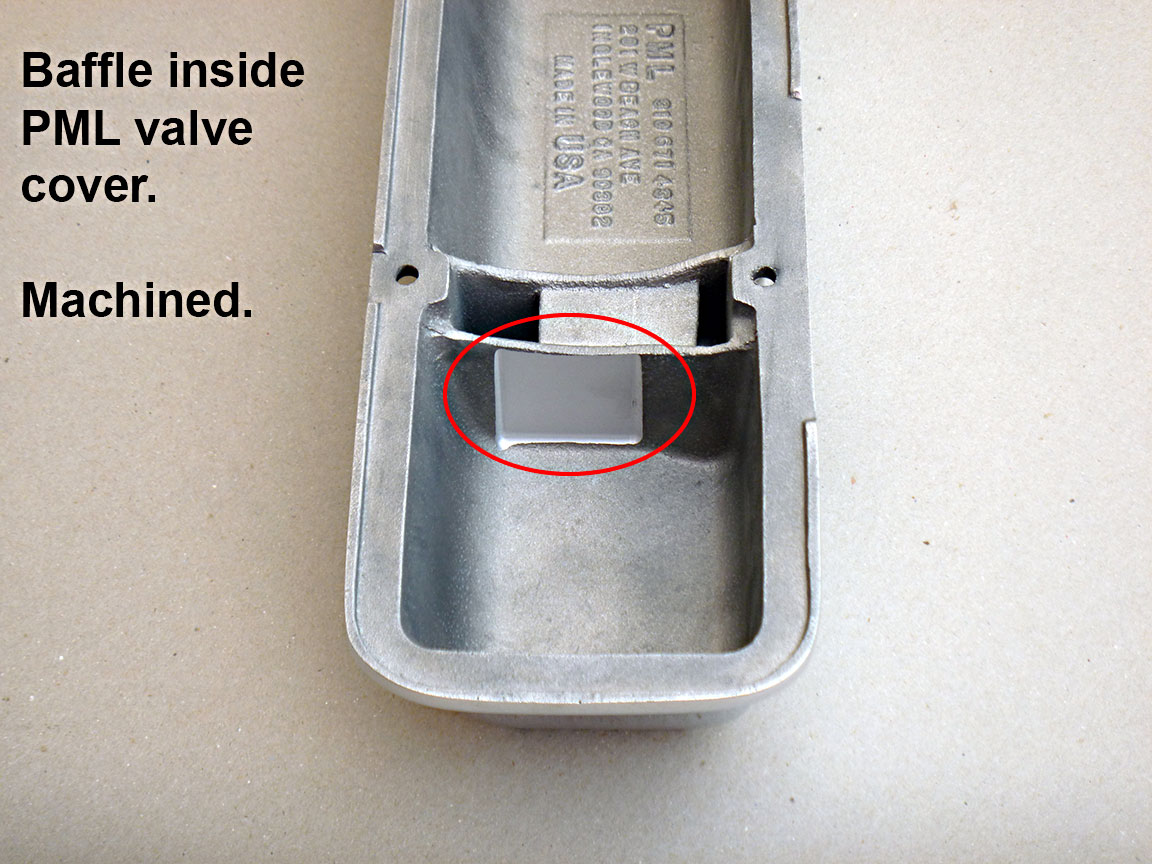

PML valve covers have a baffle on the inside. When the covers are installed, the baffle sits between roller rockers. There must be enough width and depth in that space between the roller rockers for the baffle.

The baffle is about 1.27 inches wide. For roller rockers with large pins, PML can machine the baffle for additional clearance. PML has done this for customers with various engine configurations. See Examples .

Click on image to view larger. These images show:

- Measuring the distance between the pins

- Baffle area unmachined

- Baffle area machined to add more clearance for the trunion pins - both sides of the baffle are machined

Details: There is a custom machining charge. The baffle thickness is reduced by 0.090 to 0.100 inches to about 1.16 inches. There may be some break out of the baffle. When the casting is made, the baffle thickness increases from the flange to the top. Once machined, the baffle thickness will not increase and be 1.16 inches top to bottom. Only the center of the baffle is machined. Corner areas are not machined.

If there is enough width between the rockers for the baffle in the PML cover, check for depth. Besides the roller rocker, is there anything above the gasket flange surface? For example, the shaft on shaft mounted roller rockers is very tall, almost to the top of the rocker arms and will contact the baffle.

See this PDF with Examples of configurations from customers.

PML valve covers will not work with shaft mounted roller rockers or stud girdles.

8. Understand That Oversized Springs or Rockers Can Contact PML Cover

An oversized spring may contact the baffle or the inside of the cover. A little grinding may be needed.

This customer had Edelbrock 77760 wide body rockers with a 1.5:1 ratio. PML machined clearance for the pins. The customer found that the springs also contacted the baffle and using a dremel tool removed a bit more material.

This has also been reported with some models of Crower Rockers, 1.5 stainless steel.

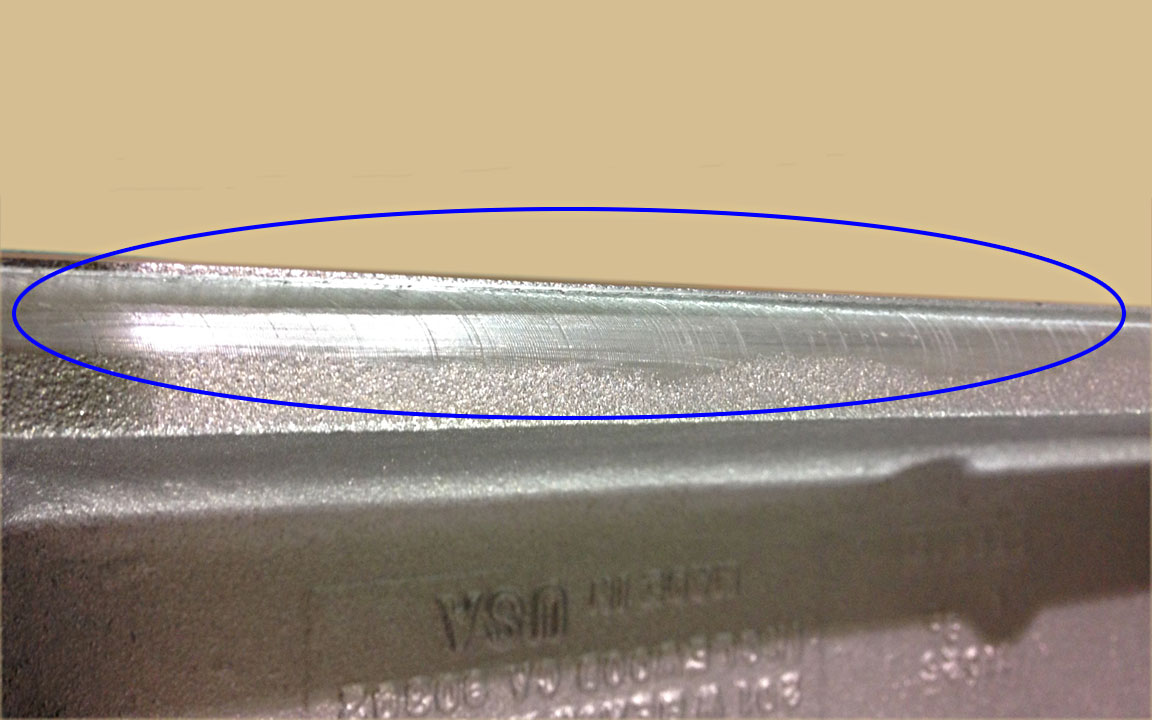

9. Identify the Cylinder Heads

PML fits each valve cover on a standard GM cylinder heads. Aftermarket heads can have a slightly different rail so the valve covers may not fit the same. PML covers have thick walls so are slightly wider than stock covers. The gasket rail is also larger. Sometimes removing part of the gasket rail or using double thick gaskets can help fit PML covers on aftermarket heads.

Picture shows the modification from a customer with Brodix heads. He found that the edge of the valve cover hit on the heads. By machining the bottom edge (not the intake manifold edge) of the valve covers, he made the gasket rail thinner and got a good fit.

After modification, PML valve covers cannot be returned so make sure this is something you are comfortable with.

10. Look at Intake Manifold

Depending on the configuration, an aftermarket intake manifold may prevent PML valve covers from seating completely on the heads. The intake side may have a ledge or extra casting material that contacts the larger PML cover at the bottom. A little grinding or a double thick gasket can help.

A customer configuration with a 350 engine had an Edelbrock intake manifold and stock heads. The customer did a little grinding to remove the extra material on the intake manifold so the valve covers would sit snuggly on the heads. (Modifications are your responsibility. PML has not done this and does not recommends this.)

11. Stud Girdles Will Not Work

PML small block Chevy engine valve covers will not work with stud girdles. Be sure you do not have stud girdles.

12. Wire Looms May Not Fit Without Modification

Wire looms that attached at the bolt holes may not fit on PML valve covers. There is about 1/16 (0.062) inch from the edge of the bolt hole to the side wall of the PML valve cover.

Some people have modified their wire loom bracket by grinding it to fit. We do not recommend modifying the valve cover in that area.

You will need new mounting bolts if you use wire looms with the PML valve covers. The bolts provided with the valve covers will not work with wire looms that attach at the bolt holes.

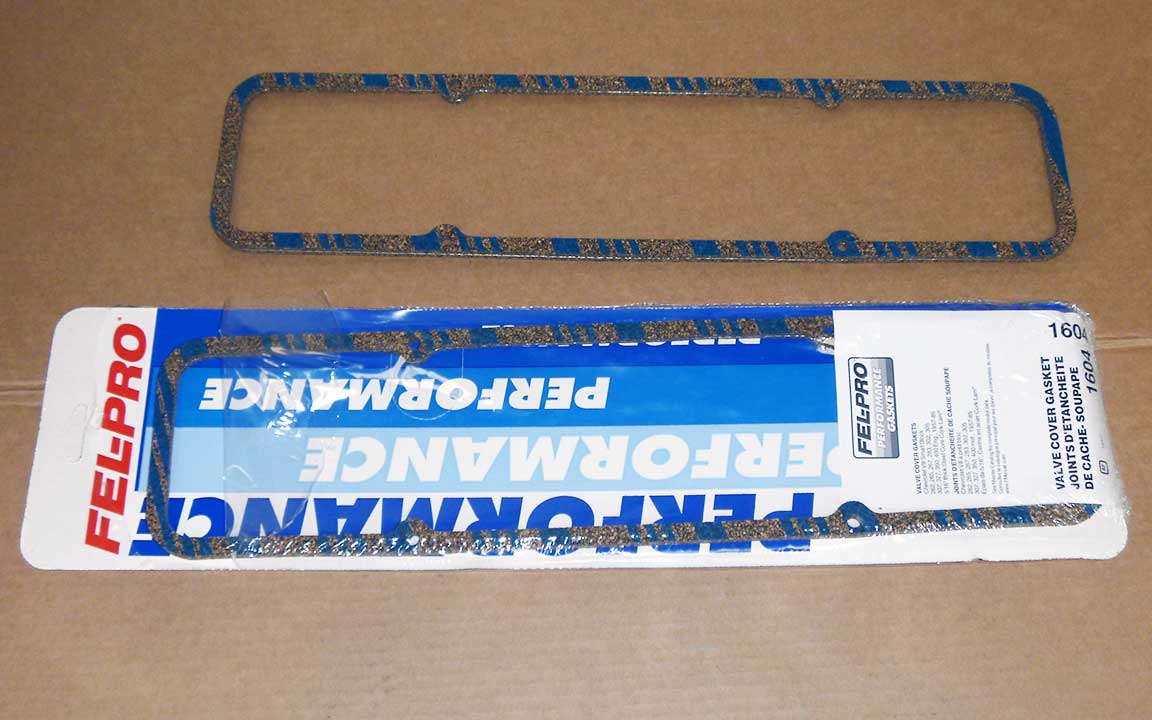

13. Gasket

PML recommends a cork or cork composite gasket. We sell some of these in under Accessories. Our gaskets are about 0.180 inches thick. This is a picture of our gasket on our valve covers.

We do NOT recommend thick rubbery gaskets or any gasket that is molded with a metal insert.

If you decide to use double thick gaskets, you might need longer bolts.

Some customers reported that they needed a little more height to add clearance. This can be helpful for adding space for roller rockers, aftermarket heads or intake manifolds.

A few customers reported that Fel Pro Performance Gaskets Part Number 1604 are about 0.300 inches thick and have worked well with our valve covers.

This information is for reference. PML has not tried these gaskets and does not have an opinion on how they fit or function.

You completed the checklist! Congrats! Contact us if you have additional questions.

General Motors Trademarks are used under license to PML, Inc.

General Motors Trademarks are used under license to PML, Inc.